How to Run a Performance Review on Your Vessel

Audience

Executive Summary

The purpose of a performance review is to verify compliance with regulatory requirements, as well as identify areas of improvement in order to optimize performance and increase efficiency. Running a performance review cannot only help you determine the competitiveness of your vessel today, but also identify what you need to do to remain so in the future.

In order to run a successful performance review is useful to identify different variables or characteristics that are important to your vessel´s specific mission/operations. To help you in this process, we have identified seven parameters, to give you a systematic approach during the review process.

This paper will first begin by outlining different higspeed vessel categories and propulsion system, then guide you through the seven performance parameters.

As a maritime professional, some of the information in this guide will be familiar to you. However, we are aimning to build on your foundation and will share new insights, to help you review your current propulsion system and identify how to optimize your vessel.

Therefore, we strive to inform and educate on the technology available today, as well as emerging products, within hybrid and electric solutions at sea. This keeps us at BOS Power on our toes and able to provide the very best of tailored vessels, optimized for efficiency and lower emissions. It also contributes to build a knowledge base for realistic and pragmatic policy making in the future.

If you find yourself interested in diving deeper into this topic, we suggest downloading the second content offer ”Manoeuvring the Propulsion Jungle” which you can find here.

The Importance Of Propulsion Systems

The propulsion system is without doubt an important part of any vessel, as it is highly linked to overall performance. In short, the propulsion system is what convert the energy generated by the engine, into a thrust that moves your vessel forward. The efficiency of this conversion is thus crusial, as it determines how much energy you require to transport your vessel from A to B.

Choosing an inappropriate propulsion system can lead to lower speed, damage, noise and poor operating/fuel economy. Consequently, the propulsion system of any vessel is considered an important investment; it can indrease the ability to compete in the marked, improve effectiveness and reduce operational costs.

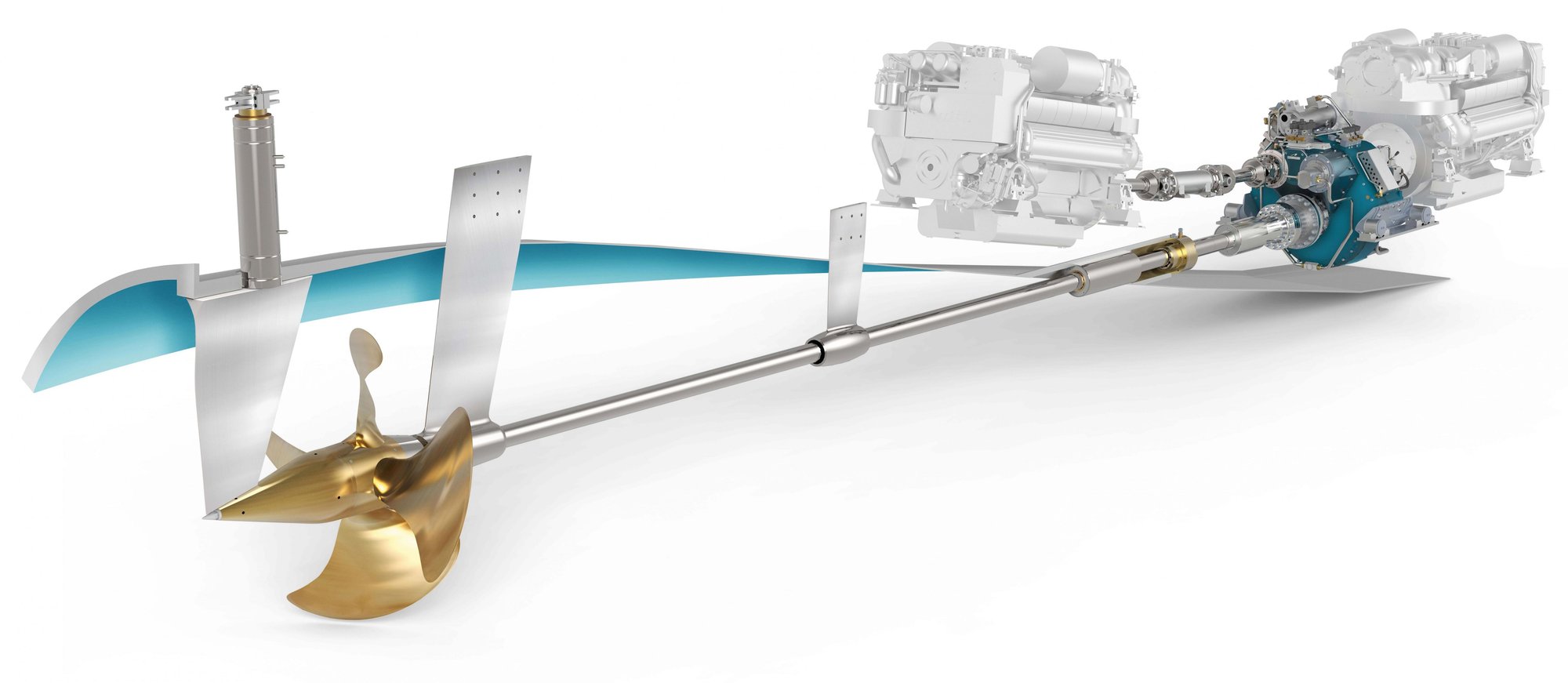

When optimising your vessel, it is crusial to look at the complete propulsion line; the engine, shaft, bracket, gear, rudder, propeller etc, which will vary depending on vessel type. For example, if you have a highly efficient propulsor, you can invest in a smaller engine. Selecting and optimizing the propulsion system/line of a vessel is perhaps one of the most practical goals, yet most challenging decisions when designing modern vessels.

High-Speed Vessel Categories

Deciding on a hybrid or electric architecture depends on several key factors, where the application or the operation profile, plays a major role.

The type of propulsion needed will vary depending on vessel types. As such, it is important that we begin by briefly outlining the different high-speed vessel categories that this guide will primarily focus on.

As already mentioned, several of the descriptions will be familiar to you as a maritime professional. However, it is important that we establish a common baseline. Our goal is to build on your foundation and share insights into what aspects are important to examine when reviewing your vessel.

Fast Feries

Fast Ferries are vessels that transports passengers, and it is from the passenger their income is generated. In addition to transporting passengers, some of the largest fast ferries also carry cars, buses, lorries etc.

The typical length of a route can vary between 10 to more that 100nmi. However, several of the shorter routes (under 30nmi) are part of a multistop journey. Fast ferries tend to have a high number of operational hours per year; approximately 5000 hours per year/12 hours per day.

Furthermore, these vessels tend to have multiple berths every single day. The top speed for these types of vessels are between 25-45 kts , and 80% of the operational profile tend to happen at this speed, hopefully fully loaded.

Fast ferries are found globally. Majority of these areas are ECA (Emission Control Area) zones, thus a special attention to emissions is advised. The emphasis on emissions will without a doubt only gain more weight in the coming years. The fuel economy and emissions needs high attention, even more in the years to come.

Workboat

There are several different types of workboats; varying from tugs, windfarm vessels to larger multicats. These vessels tend to have a small crew that are responsible for a variety of duties for different contractors on port construction/ infrastructure projects or within the offshore energy industry

Low fuel consumption is key for both the charter and offshore industry that wish to work with vessels that have a green profile. Other requirements can range from high winch capacity to subsea construction capabilities. A typical workboat, such as a windfarm vessel, are typically 20-30 meters long and carry 12- 24 passengers. For a windfarm vessel, these passengers are technicians who need to be transported safely to the windmills every morning. Furthermore, these boats often carry tools and fuel - approximately 8-10 tons in payload. The goal is to ensure that the technicians get as many hours as possible at the windfarm, not gone seasick under way to the field. The vessel that can fulfil this, is the most likely to win contracts.

Furthermore, there are two different types of workboats within harbour and terminal operations; those that provide berthing assistance (towing, pushing and line handling) and the vessels that offers general services (bouy laying, transportation, pollution control, harbour maintenance etc). Within the dredging market there are workboats of high versatility which provide services to dredgers and dredging equipment (supplying, anchor handling, maintenance support etc).

Anchor handling tugs/supply vessels are workboats that perform various operations from high-powered towing, transporting supplies to offshore installations and rescue operations. These versatile vessels require both high propulsion power for transits, in addition to lower power for dynamic positioning mode and station keeping.

Search & Rescue (SAR)

Search and Rescue vessels are another type of workboats. These are designed to performance life-saving operations, coast surveillance and support security during events at sea. As such, they are designed for “no failure” zone applications where reliability and consistency are crucial.

The SAR vessels tend to have fewer operational hours than other workboats, perhaps only a 1000 hours per year. They commonly have hull forms and arrangements that are optimized for efficient and safe operations.

SAR vessels require the ability to travel at high speed (more than 30 knots) in the roughest weather as well as havinge good operability and performance in waves. Furthermore, these vessels are known for their ergonomic arrangement, increasing capabilities such as man-overboard assistance.

Multipurpose Vessels

Multipurpose vessels are big workboats that travel at high speed. They are often split into four different categories:

- With cargo gear

- Without cargo gear

- Coastal trade liners

- Sea river vessels

Multipurpose vessels are used for a various of operations and thus have complex designs which are difficult to build. These vessels are designed for flexibility and ability to carry heavy loads in different shapes/forms. Cargoes can be rolled or lifted on board, which requires different types of loading gear.

For these vessels it is crucial to optimise the space used for payload/cargo and minimise time spent in ports/harbours. It is also important that these vessels can operate in challenging weather conditions.

Multipurpose vessels are often used offshore, where their job can for example be to transport workers to oil fields. These boats can carry some deck load, such as fuel and equipment. As such, they have big payload variation. In addition to transporting workers, these boats can also be used in assisting the moving of jack-up rigs etc. Vessels used offshore must be equipped to handle and adapt to rough seas and harsh environments.

Yachts

A Yacht is a sailing or motor vessel, designed for pleasure, cruising, or racing. There is no standard definition, instead the term yacht often applies to vessels which have a cabin with amenities making it suitable for overnight use and with aesthetic qualities. Some yachts are professionally crewed, some private owned and some owed by corporations.

Yachts are likely to measure between 33 feet (10 m) up to more than 590 feet (180 m) in length, in the superyatch/megayatch category. Super Yachts are luxurious pleasure vessels available for charter, with a staff that caters to guests at a high standard of comfort. Due to the political and public pressure to reduce the caron footprint, there are an increasing number of superyachts that are adopting hybrid technologies.

Sightseeing / Tourism

Typical features for sightseeing and tourism vessels are their capability of taking many passengers but still offering good views. As such, aluminum or carbon fibre is the preferred building material. Typcially, the vessels range between 25-40 metres and the speed varies between 18 to 25 knots.

Patrol

Energy Sources

The standard method of propulsion are diesel engines that unfortunately contribute to greenhouse gas emissions. Very often these engines tend to have a low efficiency of only 50%, causing unneccessary use of fossil fuels.

Prolusion systems driven by fossil fuels can vary from a simple diesel engine connected to a propellor shaft to more complex systems combining diesel engines with electrical generators. In general, the set-up of the propulsion system will vary depending on the size of the vessel and the operational profile.

Offshore support vessels for example, tend to use diesel electric propulsion systems with thrusters, also referred to as pods. These operate on diesel oil or natural gas. Very often, diesel oil is being utilised as it is considered a more reliable fuel.

However, with the current, strong focus on sustainability, the marine propulsion engine market is driven by the need for faster, cleaner and fuel-efficient engines. Not only due to the environmental benefits, but also because of the cost benefits associated with electric or hybrid solutions.

For example, hybrid battery installations allow diesel engines to function up to 20% more efficiently having positive effects on costs and emissions. In addition, bio-fuels are predicted to soon increase heavily in price. As such, the value of thinking fuel-efficiency is becoming much more evident across all transportation sectors.

Until recently, the problems with electric and hybrid propulsion systems are the weight and limited capacity of the batteries. Luckily, those issues are now becoming smaller every year. The shift from fossil fuels to greener energy sources is only accelerating as more environmental regulations and expectations are being introduced. This can for example be seen in Norway, where the government has announced that it requires all ferries along its coastline to be electrified by 2030.

Propulsion Categories

To begin with, vessels used sails and paddles to convert energy into movement. However, new systems were developed during the industrial revolution, allowing vessels to travel at a faster speed without being reliant on wind and manpower.

These systems are actually not too different from those used today, however they have been further developed in many different directions. In recent years there has been a strong focus on developing new propellors and propulsions systems that not only increase efficiency and performance, but that can reduce overall emissions.

In this chapter we will explore three different propulsion systems common for high-speed vessels:

- The Water Jet (WJ)

- The Fixed Pitch Propellor (FPP)

- The Controlled Pitch Propellor (CPP)

The aim is to provide a brief description of how these systems work, their possibilities and limitations

%20Propulsion%20Systems%20from%20Servogear.jpeg?width=1000&height=295&name=Controllable%20Pitch%20Propellers%20(CPP)%20Propulsion%20Systems%20from%20Servogear.jpeg)

The Water Jet

The Water Jet is a propulsion system that propels vessels by a reaction force, generated by high-speed jetting of the water stream. With this system the propelling force is generated by adding momentum to the water by accelerating a certain flow of water in an astern direction.

Simply put, the water jet is a pump that through increasing the speed of the water, creates a thrust which makes your vessel move forward. The water jet is commonly used for high-speed vessels that require shallow draught, protected propulsion, high manoeuvrability, low noise and vibrations.

The Fixed Pitch Propellor

The Fixed Pitch Propellor is the simplest of propulsion systems; it has a standard propellor with a fixed design. As suggested by its name, it is fixed and unchangeable, meaning it is not possible to adjust the solution over time.

The only thing you can do to change the speed of vessels with this propulsion, is to increase the RPM of the shaft; you add more power, the shaft goes faster, causing the propulsion to push more. If you wish to change the direction of the vessel going from forward to aft, you have to change the directional rotation of the shaft and the propellor. As such, this propellor tends to work best for those vessels used for a stable speed and low variation of payload. Furthermore, this propellor has limitations in terms of manoeuvrability.

There are different variations of the FPP, with thicker propellor blades that work better for vessels operating at a low speed and in areas with floating debris. The thickness of the propellor blades and its durable material, help make it more robust and thus protect it from damages.

The Controlled Pitch Propellor

Controllable pitch propellors (CPP), also referred to as Variable Pitch Propellors, have a fixed diameter of the blades adapted to the vessel, however a changeable pitch. Meaning that the propeller blades can be dynamically adjusted during an operation through turning the angle of attack.

Consequently, this propulsion system can be used to run the vessel in forward and astern direction both, without having to change the direction of rotation of the shaft. By adjusting the angle of attack, you are also able to determine the amount of propulsive force produced.

This makes it possible to adjust the load on the driveline when generating power. As you are well aware of, it is often the diameter or size of the propellor that determines how much power can be absorbed, whilst the pitch controls the forward advance. However, the CPP with its adjustable pitch is able to change the speed of the vessel without increasing the speed of the propellor. This is ideal for vessels operating at fixed speed, but have the need of added thrust.

The CPP with its adjustable propellors can thus help get the most of out the engine, propulsion system and application. Very often this system can seem more complex at first, however it is based on proven technology that has been around for over 100 years, and has typically been used in displacement vessels and within Nordic countries.

Performance Review

The purpose of a performance review is to verify compliance with regulatory requirements, as well as identifying areas of improvement in order to optimize performance and increase efficiency. The scope of a performance review varies, but usually includes an assessment of the hull, engine, gear/shaft line, propellor and rudder.

Running a performance review of your vessel cannot only help determine where your vessel is today, but where you should be in the future. In other words, help you pin-point the gap between the current performance of your vessel vs. the optimal.

Every maritime professional knows that there is no such thing as designing the perfect vessel. Instead, it is all about finding the right balance between the different performance parameters. It is through this game of compromising, the ship designers manage to create a vessel which is optimized for its specific operational style.

Achieving an optimized vessel, tailored to its specific mission is not only about speed and manoeuvrability, but also energy consumption. As climate change is a global issue, influencing regulations and taxes as well as pointing out a moral and ethical responsibility to all of us, sustainability is an expectation from both authorities and customers.

To be competitive both now and in the future, you need to prove that your vessel is efficient in terms of cost and time, reliable and sustainable. Optimizing the performance of your vessel is therefore an important investment, which can increase your success when competing in the market. However, there are a lot of variables which come into play. In the next chapter we will dive into some performance parameters that will help you to make the right choices.

Performance Parameters

In order to choose the right propulsion system, it is important to consider the different variables or characteristics that are important to your company/organisation. In light of this, we have outlined the seven major performance parameters that you should consider, regardless of vessel type.

The seven criteria are:

- Economy

- Environment

- Versatility

- Reliability

- Safety

- Adaptability

- Comfort

Although the performance parameters are the same for every vessel type, their importance will vary. For example, a fast ferry that needs to go 35 knots, needs to do so a set number of times every day. In contrast, a yacht might also need to go 35 knots.

However, it is not as important that it is able to do so every day for 12 hours. In other words, the fast ferry and the yacht might require the same top speed, but it is likely that the fuel economy will be a much higher priority for the fast ferry.

In other words, the fast ferry and the yacht might require the same top speed, but it is likely that the fuel economy will be a much higher priority for the fast ferry.

Another example is a rescue vessel that must be able to reach a destination within a short time span and have good manoeuvrability. Simultaneously, it needs to be able to pull a boat, hence have a strong bollard pull. In other words, you require a fast tugboat.

However, it does need the ability to do this operation every single day, but it must be able to do so when it is needed.

The importance of each parameter is also depended on fuel type. By using fossil fuels, you can fill the tank almost anywhere, as in contrast to batteries. When using batteries, the energy power that you can store is dramatically reduced. In addition, there are limited locations where you can charge them.

Furthermore, charging batteries does not take minutes, but hours. In addition, the batteries take up space, hence you can carry/store less onboard – your payload is reduced. In general, if you must fill the boat with energy instead of passengers, it is not the optimal boat.

For all vessels the reduction of energy consumption is particularly important, and for the future, when the cost of energy and emissions is predicted to increase, even more important.

Economy

There are two main economic categories: Captial Expenditure (CAPEX) and Operating Expenditure (OPEX).

CAPEX refers to the funds used to acquire and upgrade your vessel, whilst OPEX are shorter-term expenses required to meet the ongoing operational costs.

The longest period of any vessel’s life is after it’s been taken into operation, as such the OPEX will over time exceed the CAPEX several times. Consequently, a higher CAPEX can be justified if it can substantially decrease the OPEX.

When optimising your vessel, it is crucial to look at the complete propulsion line; the engine, shaft, bracket, gear, rudder, propeller etc, which will vary depending on vessel type.

For example, if you have a highly efficient propulsor, you can invest in a smaller engine - thus lowering the CAPEX. Similarly, if you have a zero emissions vessel, aim to invest in the propulsion system that has the highest available efficiency - thus reducing the number of battery packages needed and therefore also the amount of weight you have to carry

Batteries are representing a big portion of the CAPEX for the complete propulsion line, and it makes sense to reduce the need.

To summarize, the goal of your CAPEX should always be to get into a positive design circle, and the key to entering that circle is to ensure that you have optimised the propulsion line together with the whole system, and operational profile. In other words, reduce the energy consumption as much as possible.

How to choose the best propulsion system for your boat, is one thing. However, ensuring that you get the gain of this choice and operate in a way that reduces costs, is much more challenging. In order to do so, it is recommended to look beyond the initial cost of equipment and focus on making the operation as cost-effective as possible.

There are four major components of OPEX of any vessel, in prioritized order:

- Fuel (The far biggest component)

- Salary • Finance & Insurance

- Maintenance

Investing in the right propulsion system can primarily influence fuel cost and maintenance cost. All reduced costs here will directly influence the bottom-line.

Environment

Environment and economy are strongly linked together. As mentioned above, one of the biggest components of the OPEX is fuel costs.

In fact, it can for highspeed-vessels cover as much as 50% of the total OPEX. Consequently, there is a huge potential for costs savings within this area alone – and the bigger the fleet, the more you can save. Furthermore, decreasing the fuel consumption also reduces the environmental footprint with the same percentage.

Today, there is a collective strive towards zero emissions, causing the price of releasing CO2 and NOX emissions to increase every year.

Furthermore, stricter regulations are being introduced and it is crucial to ensure that you do not put a vessel into operation, without it meeting the current environmental requirements and having the ability to meet future, more strict regulations.

The key is not only to become as efficient as possible, but to also operate as smart as possible. When having a zero-emission engine you need electricity. That electricity must come from an energy source, for instance a battery.

The challenge is to use as little energy as possible. If you can limit the energy consumption, you also lower the amount of energy you need to carry. In return, you are left with a higher payload.

It is also important to ensure that the vessel does not have any oil spills. In addition to the environmental consequences, oil spills might have financial repercussions in the form of huge fines.

Furthermore, it is predicted that noise pollution will gain more focus on the coming years, hence it is recommended to choose a propulsion system that makes less underwater noise.

Versatility

Versatility is another important factor that should be considered when reviewing your vessel plans. The more functions your vessels have, the better the initial investment. Some vessels are designed only for one purpose. However, if you can manage to make it more versatile it can have major benefits.

For example, a vessel that is energy efficient in different, wider operation profiles can allow you to get a range of different jobs, consequently making you very competitive. In other words, the choice of propulsions can make you more flexible and secure an increasing number of contracts, and by this the payback time of the investment is reduced.

Furthermore, versatility/flexibility is hugely linked to utilization rate. For instance, having the combination of both high-speed capabilities and high towing capabilities, increase the type of task you can do. With an efficient propulsion system, you can increase the range, decrease the fuel consumption, and perhaps also utilize other types of energy sources.

For SAR vessels, it is particularly important to focus on ensuring a combination of high speed and high bollard pull. Whilst payload variation is more important for fast ferries carrying passengers and workboats at windfarms, who need flexibility to be able to maintain speed with high payload.

Reliability

Reliability is about being fit for purpose and have the correct equipment to do the job. This must be secured in the earliest design-phase of the vessel, when the operational profiles and capabilities are being decided.

More specifically, it also refers to having the equipment properly maintained and ensuring that it is working optimal without breaking down.

The keyword here is predictability - the equipment should be able to work efficiently - always.

Safety

Safety is very important for clients, and they are measured on it. You might also say that everybody wants to get a good night of sleep and not worry that there might be an accident to their crew or clients due to their operations.

The propulsion system affects the safety in different ways:

-

Safety of equipment

The equipment is reliable and does not break down causing accidents. -

Safety of the complete vessel

What is the crash-stop lenght? How quickly can you stop the vessel when you are driving at full speed? How is the responsiveness in an avoiding manoeuvre? How is the steering/stopping ability if the system suddenly falls out? -

Redundancy

More drivelines, separated controls and energy sources do increase the redundancy, and reduces the risk for not being able to handle the vessel. -

Quality and reliability

All major propulsor system has their pros and cons – but in general all systems of today are good in this sense.

Adaptability

It has become increasingly important for vessels to be easily adaptable. Due to the recent developments of new energy sources and new technologies, it is recommended to invest in equipment that can be adapted throughout the next 20 years.

In particular, if you have a vessel that runs on diesel fuel, it is wise to invest in systems that in the future can operate on new energy sources, with high efficiency. Thus, ensure durability for the investment over many years. Reducing the energy consumption will always be a good choice.

Comfort

The propulsion system is responsible for two elements that disturbs a passengers’ comfort: Propeller induced noise and vibration. Noise and vibration are highly linked together and can in some cases be quite visible.

Ensuring a low level of both these categories is possible through optimising the propulsion systems in the design phase. It is always possible to optimize the systems together with the hull-shape with this in sight.

Reduced noise and vibration from the propulsion system including engines and exhaust are particularly important for passenger vessels, such as fast ferries and tourism/sightseeing vessels and yachts.

Manoeuvrability

Manoeuvrability refers to how well you can handle your vessel. For instance, when you are berthing your vessel, how is the responsiveness? The quality of being easy to move or steer while in motion, is crucial for the overall performance of the vessel/operation.

For vessels that have several berthing’s in harsh weather conditions, such as windfarm vessels, this criterion is crucial. Furthermore, manoeuvrability can influence other aspects of an operation, such as time spent and fuel consumption. If you have a fast ferry that undergoes multiple dockings every single day, better manoeuvrability can reduce the time you use for each stop. And by this, you might reduce the speed in the route- and save fuel.

Conclusion

We have now guided you through seven important parameters to help you review your current propulsion system and identify areas of improvement.

Bear in mind that every vessel is unique. In order to design a vessel optimized for its specific operational profile, we thus recommend that you begin by identifying which of the seven parameters that are most crucial for your vessel’s operational success.

If you wish to dive deeper, we suggest checking out our second paper: ”Manoeuvring the Propulsion Jungle”. This guide outlines the strengths and weaknesses of the three most common types of propulsion systems and give some general recommendations on what aspects to prioritize, based on typical operational profiles.

Get in Touch

Do you want to learn more about our solutions or discuss how we can support your next project? Our team of experts is ready to answer your questions and explore opportunities together.- Let’s talk about your needs

- Share your ideas with us

- Start building a sustainable and reliable future today

Want to save the case study or share it with a colleague?

Download a PDF version – perfect for reading later or forwarding to your team.