%20Propulsion%20Systems%20from%20Servogear.jpeg?width=300&name=Controllable%20Pitch%20Propellers%20(CPP)%20Propulsion%20Systems%20from%20Servogear.jpeg)

Manouevering the propulsion jungle

Audience

Executive Summary

The propulsion system is without doubt an important part of any vessel, as it is highly linked to overall performance. Choosing the wrong propulsion system can lead to lower speed, damage, noise and poor operating/fuel economy.

The propulsion system of any vessel is considered an important investment; it can increade the ability to compete in the market, improve effectiveness and reduce operational costs.

As a maritime professional, some of the information in this guide will be familiar. However, our goal is to build on your foundation and share new insights to help you determine the right system for your vessel.

This guide will begin by briefly outlining the seven most important performance parameters to help you make the right choice.

Furthermore, it will discuss the strengths and weaknesses of the three most common types of propulsion systems and give some general recommendations on what aspects to prioritize, based on typical operational profiles.

It is important to keep in mind that every vessel is unique. Consequently, this guide cannot provide a universal recipe for optimal performance.

Performance Parameters

In order to choose the right propulsion system, it is important to consider the different variables or characteristics that are important to your fleet. In light of this, we have outlined the seven performance parameters that you should consider, regardless of vessel type.

The seven parameters are:

- Economy

- Environment

- Versatility

- Reliability

- Safety

- Adaptability

- Comfort

Although the performance parameters are the same for every vessel type, their importance will vary. For example, a fast ferry that needs to go 35 knots, needs to do so a set number of hours every day. In contrast, a yacht might also need to go 35 knots. However, it is not as important that it is able to do so every day for 12 hours.

In other words, the fast ferry and the yacht might require the same top speed, but it is likely that the fuel economy will be a much higher priority for the fast ferry.

*The following is a short summary of the seven parameters. For the full description please check out our paper ”How to Run a Performance Review on Your Vessel”.

Economy

There are two main categories: Capital Expenditure (CAPEX) and Operating

Expenditure (OPEX).

CAPEX refers to the funds used to acquire, upgrade and maintain your vessel, whilst OPEX are shorter-term expenses required to meet the ongoing operational costs. The OPEX will over time exceed the CAPEX several times. Consequently, a high CAPEX can be justified if it can substantially decrease the OPEX.

There are four major components of OPEX:

- Fuel (The far biggest component)

- Salary

- Maintenance

- Finance & Insurance

Investing in the right propulsion system can primarily help you lower fuel cost and maintenance cost. All reduced costs here will directly influence the bottom-line.

Environment

Environment and economy are very strongly linked together, as one of the biggest components of the OPEX is fuel costs. In fact, it can cover as much as 50% of the total OPEX.

Consequently, there is a huge potential for costs savings within this area alone – and the bigger the fleet, the more you can save. Furthermore, decreasing the fuel consumption also reduces the environmental footprint with the same percentage.

As stricter regulations are being introduced, it is crucial to ensure that you do not put a vessel in operation, without it meeting the current environmental requirements.

Versatility

Versatility is another important factor that should be considered when reviewing your vessel. The more functions your vessels have, the better the initial investment. Some vessels are designed only for one purpose.

However, if you can manage to make the vessel more versatile it can have major benefits. For example, a vessel that is energy efficient in different, wider operation profiles can allow you to get a range of different jobs, consequently making you very competitive.

Reliability

Reliability is about being fit for purpose and have the correct equipment to do the job. This must be secured in the earliest design-phase of the vessel, when the operational profiles and capabilities are being decided.

More specifically, it also refers to having the equipment properly maintained and ensuring that it is working optimal without breaking down.

The keyword here is predictability - the equipment should be able to work efficiently - always.

Safety

Safety is very important for clients, and they are measured on it. You might also say that everybody wants to get a good night of sleep and not worry that there might be an accident to their crew or clients due to their operations.

The propulsion system affects the safety in different ways:

-

Safety of equipment

The equipment is reliable and does not break down causing accidents. -

Safety of complete vessel

What is the crash-stop length? How quickly can you stop the vessel when you are driving at full speed? How is the responsiveness in an avoiding manoeuvre? How is the steering/stopping ability if the system suddenly falls out? -

Redundancy

More drivelines, separated controls and energy sources do increase the redundancy, and reduces the risk for not being able to handle the vessel. -

Quality and reliability

All major propulsor system has their pros and cons – but in general all systems of today are good in this sense.

Adaptability

Due to the recent developments of new energy sources and new technologies, it is recommended to invest in equipment that can be adapted throughout the next 20 years. In particular, if you have a vessel that runs on diesel fuel, it is wise to invest in systems that can be adapted and operate on new energy sources in the future. Thus, ensure durability

Comfort

The propulsion system is responsible for two elements that causes a disrupt of a passengers’ comfort: Noise and vibration. Noise and vibration are highly linked together. Ensuring a low level of both these categories is possible through optimising the propulsion systems. Noise and vibration are particularly important for passenger vessels, such as fast ferries, tourism/sightseen vessels and yachts.

Manoeuvrability

Manoeuvrability refers to how well you can skilfully move or guide your vessel. For instance, when you are berthing your vessel, how easy is it to park, to turn, slow down, accelerate and stop? The quality of being easy to move or steer while in motion, is crucial for the overall performance of the vessel.

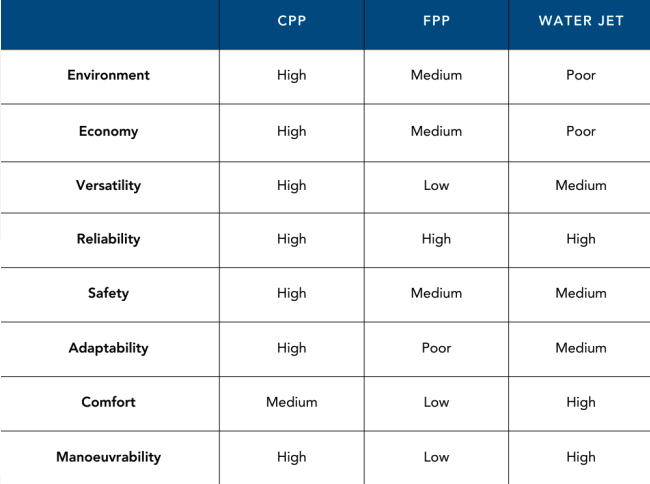

Propulsion Categories

In this part, we will discuss the pros and cons of the three most common propulsion- system concepts:

- The Water Jet (WJ)

- The Fixed Pitch Propellor (FPP)

- The Controlled Pitch Propellor (CPP)

Each propulsion system will be outlined in relation to the different performance parameters mentioned in the section above. The aim is to give you a brief overview over the various systems, to help you identify the best fitted solution for your vessel.

%20Propulsion%20Systems%20from%20Servogear.jpeg?width=1000&height=295&name=Controllable%20Pitch%20Propellers%20(CPP)%20Propulsion%20Systems%20from%20Servogear.jpeg)

The Water Jet

The water jet has high maneuverability and is great for operations in shallow waters. Due to the nature of its technology, the water jet produces very little vibration and noise – thus give a pleasurable experience to its passengers. Furthermore, the low vibration and noise also allow the animals to remain undisturbed. Additionally, the water jet is less disturbed by debris in the water.

The water jet has quite good efficiency when operating at a very high speed (40-50 knots). Furthermore, with this type of propulsion system, it is common to install four water jets (four engine installations), meaning that the vessel is made redundant; if anything were to happen to one of the engines, you are still able to get your passengers back home.

The maintenance cost of the water jet is not very high. Additionally, with the water jet you are not loading the engine too much, and thus the maintenance intervals are extended.

The water jet has a higher CAPEX than FPP, it is approximately on the same level as a CPP installation. Furthermore, the water jet can be up to 30% less effective than a well-designed CPP. Consequently, it requires you to invest in bigger and more expensive engines than with a CPP to perform similarly.

The efficiency is sensitive to weather conditions and is easily reduced when there are waves or wind hitting the vessel.

The acceleration and retardation of a water jet is quite slow, and the crash stop length is higher than with the CPP.

However, the biggest con of the water jet is the OPEX - more specifically, the fuel consumption. With a CPP the fuel consumption can be reduced by approximately 30%.

The efficiency curve has a steep fall when slowing down the speed (from 50 knots to 20- 30 knots ) and is very sensitive to the variation of payload. This means that if the payload increases, it negatively affects the speed and efficiency.

The Fixed Pitch Propeller

The FPP is the cheapest solution in terms of CAPEX; The propellers and shaftline itself are low in cost and have a simple design, with very few moving parts.

In its design condition/point (speed x and vessel-weight y) it can have a high efficiency.

The FPP has a simple design, with very few moving parts. Furthermore, the propellor is changeable and spare parts are of high availability as there are many suppliers on the market.

The FPP efficiency falls quite fast outside its design speed. In order to improve the efficiency for different speeds, you will need to dock the vessel and change propellers, ie having multiple proellers in your spare stock.

The FPP is sensitive to payload variations, giving reduced efficiency.

The FPP will often overload your diesel engine in the real operation outside the design point, giving high maintenance cost for your engine.

The vibration and noise are higher with an FPP, than with a water jet.

The FPP gives low flexibility of the efficient operations for your vessel, due to its nature

Lastly, the FPP requires you to have a reversing gear. This means that every time you are manoeuvring the vessel, you have to clutch in/out to change the rotation of the propeller. As a result, you can get more wear and tear on the gearbox itself.

The manoeuvrability of your vessels is not optimal.

The Controlled Pitch Propeller

The CPP is efficient in a wide speed-range, giving the best overall efficiency, and by this reduced fuel cost and emissions. Furthermore, this propulsion system is flexible to payload variations. Due to its versatility, the vessel is thus able to obtain a good fuel efficiency (OPEX). The reduced energy consumption enables Zero Emission energy sources to be utilized more efficient.

The CPP is also the most adaptable propulsion system. In other words, it is much easier to adapt the CPP to batteries, hydrogen or new fuels with lower energy density than diesel, compared to the water jet and FPP.

The CPP has pitch adjustment possibilities. Consequently, you can get high efficiency in a wide range of operational profiles and avoid any overload to the engines. In addition, the CPP has good manoeuvrability and trust capabilities (high bollard pull/push).

The maintenance cost of the installations (engine with propellors) is low. Due to the engine never being overloaded, it is also very common for the maintenance intervals to become extended.

Safety is improved due to very responsive manouvring and crash-stop capabilities, compared to WJ and FPP.

Comfort for the passengers is often improved with a CPP compared to FPP, due to less vibration from the propeller when you can optimise the pitch in any speed.

The CPP has less propellor blades than a water jet, thus can have a slightly higher vibration and noise. Furthermore, this propulsion system is more complex than the FPP.

The CAPEX is often higher than for an FPP solution, considered to be at the same level as a WJ solution.

The CPP can work well in all vessel categories, unless it has a very fixed/stable operational profile.

- Lower/stable speed > maybe FP is better (good enough)

- Very high/stable speed > maybe water jet is better

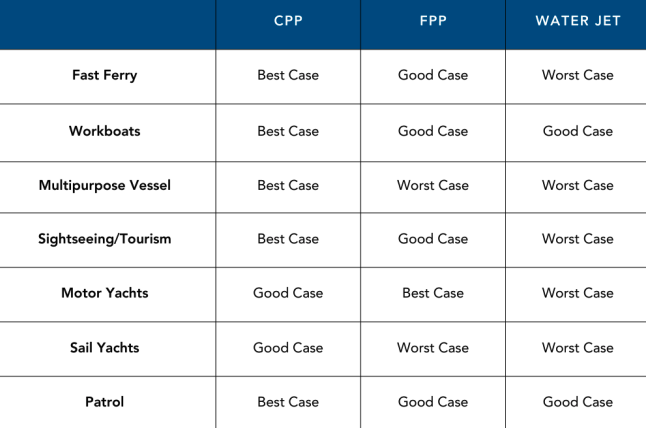

Vessel Types & Their Operational Profile

As mentioned earlier, the performance parameters are the same for every vessel type, however their importance will vary. In order to find the best propulsion system for your vessel, it is thus important to examine the operations the vessel is required, as well as expected to perform.

This section will thus outline the typical operational profile for each vessel type. Based on this, it will draw a conclusion based on what criteria that should be prioritised. The aim is to provide some general recommendations. Bear in mind that despite being within the same vessel category, not every vessel will have the same operational profile.

Fast Ferries

Fast Ferries are vessels that transports passengers, and it is from the passenger their income is generated. A typical fast ferry has a high number of operational hours per year; approximately 5000 hours per year/12 hours per day. Furthermore, these vessels tend to have multiple berths every single day. Consequently, the vessel requires good manoeuvrability to reduce the time during berths and must be efficient during high speeds. Both these two aspects are crucial for the overall fuel consumption and emissions.

For fast ferries it is common for 80% of the operational profile to happen at top speed, with (hopefully) all seats filled.

This is also when the fuel consumption is at its peak. Hence, it is crucial for fast ferries to optimize this part of the operations as much as possible. In fact, the fuel consumption for a fast ferry can be approximately 50% of the overall OPEX. Not surprisingly, you can thus easily achieve costs-savings of more than 30% through proper optimization.

For fast ferries, the overall comfort is also an important factor, however this has more to do with ensuring happy passengers, rather than saving costs. Out of the three propulsion categories, it is the Water Jet that produces the least noise and vibration, closely followed by the CPP.

Typical operational requirements:

- 4500 hours/year

- 32 knots

- 400 Passengers inc luggage and fuel

- Payload variation 50 tonnes

- Highspees operation in schedule: 32 knots 80%

- Harbour at slow speed (5-10 knots) 10%

- Habour, Manouvering 15 berthings pr day 10%

Workboats

A typical workboat, such as a windfarm vessel, are typically 20-30 meters long and carry 12-24 passengers. For a windfarm vessel, these passengers are technicians who need to be transported safely to the windmills every morning.

Furthermore, these boats often carry tools and fuel - approximately 8-10 tons in payload. The goal is to ensure that the technicians get as many hours as possible at the windfarm. The vessel that can fulfil this, is the most likely to win contracts.

These types of boats are out on open sea, and thus should be able to manoeuvre well in high waves, strong winds and currents. Typically, they are out 12 hours a day (3000-4000 operations per year). For most of the time they travel at 30 knots (high speed).

The windfarm workboats must be able to push the bow quite hard towards the windmill in order to transports its passengers onto the windmill. When the boat is in the correct position, and the movements of the boat are controlled, the technicians move from the deck of the boat and onto a ladder.

In order to safely transport its passengers onto the windmill it is thus crucial to have high bollard push/pull.

A typical operational profile:

- 10% High-speed light ships without many passengers

- 50% Full payload

- 5% Harbour & Manoeuvring

- 30% Docking (happens at least 24 times a day if there are 12 tech

- 5% Idling

From this we can estimate that the biggest cost-driver is the high-speed operation at full load, and the docking at the windmill where the engines are being heavily loaded. Hence, these operations is at cover around 80% of the time- but close to 95 % of the fuel consumption. Completing these operations in an efficient manner is thus crucial.

In addition to efficiency, reliability and safety are also important factors. As the workboats often are out on rough sea, it is important that they are able to operate during the weather window agreed upon in the contracts.

SAR

A typical operational profile:

- 1000 hours/year

- Highspeed operation 35 knots 30 %

- Idling, searching, harbour manouvering (5-10 knots) 40 %

- Towing, High bollard pull 30 %

These vessels need to be able to travel in the roughest weather and move out to location quickly. As such, the propulsion systems have to provide these boats with good ability to operate at strong winds, currents and big waves at both high and low speed.

Furthermore, the manoeuvrability is key, as the SAR boats must be able to move controlled and safely towards a ship in distress, or where there are people in the sea. Lastly, the SAR vessels require good towing capabilities.

To summarize, comfort and the OPEX is less of importance compared to the manoeuvrability, reliability, versatility and high bollard pull. The number one priority of this boat is to save lives.

Multipurpose Vessels

Multipurpose vessels are big workboats that travel at high speed. Their job is to transport workers to the oil fields. These boats can carry some deck load, such as fuel and equipment. As such, they have big payload variation.

In addition to transporting workers, these boats can also be used in assisting the moving of jack-up rigs etc. Consequently, the two most important abilities are high bollard push/pull and high-speed travel.

Similarly, to workboats, multipurpose vessels have many operational hours a year. Some of these vessels also require a good DP capability so that they can sit in a position under the rig safely (manoeuvrability).

A typical operational profile:

- 5000 hours/year

- 32 knots highspeed

- Towing

- DP capabilities

- 60 Passengers + various deckload

- Payload variation 200 tons

- Highspeed operation in schedule light ship: 32 knots 20%

- Highspeed operation full payload: 28 knots 50%

- DP and harbour manouvering (5-10 knots) 20%

- Towing 10%

Yachts

As sustainability is continuously getting more focus, there is an expectation in the market to make the super yachts as green as possible. Increased emphasis is put on the overall energy consumption to reduce emissions and demonstrate climate awareness.

Motor

The motor yachts are the vessel type that tends to have the fewest operating hours per year. Very often they spend much of their time sitting in different harbours as well as idling. As these vessels travel few hours at high-speed, fuel consumption is less of a priority than it is for workboats and fast ferries.

However, for those motor yachts that travel over longer distances and to more remote places, fuel consumption will be taken more into account. Manoeuvrability and comfort are important factor for these boats, regardless of travel distances.

Sail

Sail yachts have similar operational profiles as the motor yachts, however due to their ability to use sails they have a lower fuel consumption. These boats are not very compatible with fixed pitch propellors, as it is not ideal for operations that require high manoeuvrability.

The optimal propellor for this type of boat has blades with the ability to eliminate water resistance as much as possible, thus the CPP is an ideal choice.

Sightseeing / Tourism

Sightseeing vessels do not operate much at high speed, as they spend more time cruising at low speed and idling.

The tourists’ need to travel with zero emissions is increasing, consequently for this vessel category it is important to examine the fuel consumption. Zero emissions vessel that use renewable energy are able to provide its passengers with as much comfort as possible (due to being low in noise and vibrations, as well as there is no smell from the exhaust). The challenge for an electrical vessel, is to carry the high load in batteries. These vessels thus require an energy efficient propulsion system.

A sightseeing vessel running on fuel, also need to be very energy efficient, with low emission, to be able to compete with electric vessels. Typically, a sightseeing vessel has an operational profile where 50% of the time is spent going at full speed (20knots) while the other 50% spent idling (6knots). The fuel efficiency of the propulsor is therefore crucial.

Patrol

The patrol vessels need to be able to travel at high speed. Furthermore, they spend a high percentage of their operational hours idling and low loitering

Very often, patrol vessels tend to not travel over large distances, but rather stay within a smaller area. Despite this, the vessel together with the crew needs to be prepared to take action should anything unexpected happen. As such, they need to be able to cover a wide range of distance, at a short time. Hence, require versatility.

The payload variation onboard is normally at zero. The most distinct difference in load is that they depart with full tanks and arrive with empty tanks. Although these vessels require good manoeuvrability, it is primarily the range and speed ability that are crucial.

When the fuel consumption is an important factor the CPP is worth considering. If fuel consumption is less important, the water jet may be a good choice as well. However, the downfall of the water jet occurs as soon as you go into slow speed and loitering.

General Recommendations

Conclusion

We have now guided you through the pros and cons of different propulsion systems.

The propulsion system is without doubt an important part of any vessel, as it is highly linked to overall performance. Choosing the wrong propulsion system can lead to lower speed, damage, noise and poor operating/fuel economy. Consequently, the propulsion system of any vessel is considered an important investment; it can increase the ability to compete in the market, improve effectiveness and reduce operational costs.

This guide has discussed the pros and cons of different propulsion systems. The aim was to help you determine the optimal propulsion system for your vessel. In addition, we have given general recommendations based on operational profiles, that we hope can be of value.

It is important to keep in mind that every vessel is unique. Consequently, this guide cannot provide a universal guideline for optimal performance. As such, we recommend that you get someone to examine your vessel, in order to help find your optimal fit-for-purpose solution.

Get in Touch

Do you want to learn more about our solutions or discuss how we can support your next project? Our team of experts is ready to answer your questions and explore opportunities together.- Let’s talk about your needs

- Share your ideas with us

- Start building a sustainable and reliable future today

Want to save the case study or share it with a colleague?

Download a PDF version – perfect for reading later or forwarding to your team.