Enhancing Electric Sightseeing Propulsion

INTRODUCTION

Achieving zero-emission shipping demands more than just swapping fossil fuels for electricity – it requires smart, energy-efficient solutions.

For high-speed passenger vessels, optimising efficiency is critical, as every kilowatt conserved means greater range, shorter charging times, and reduced operating expenses.

As one of the world’s first and fastest fully electric sightseeing catamarans, MS Rygerelektra represents a significant step forward in sustainable maritime tourism. Operated by Rødne Fjord Cruise, Norway’s largest family-owned fast ferry company, the vessel provides an emissions-free journey through the Lysefjord – home to the world-famous Preikestolen (Pulpit Rock). In winter season, tourists from all around the world can enjoy one daily round trip. During the summer’s high-season, MS Rygerelektra makes two daily round trips.

Designed and built by Brødrene Aa in 2020, the vessel features a lightweight carbon fibre hull to maximise energy efficiency while ensuring optimal performance across varying passenger loads and operational conditions. To further enhance energy efficiency and support the vessel’s operational profile, MS Rygerelektra is equipped with Servogear’s Ecoflow Propulsor™ – a controllable pitch propeller (CPP) system engineered to reduce energy losses and improve vessel handling.

%20Propulsion%20Systems%20from%20Servogear.jpg?width=1000&height=782&name=Controllable%20Pitch%20Propellers%20(CPP)%20Propulsion%20Systems%20from%20Servogear.jpg)

MAXIMISING EFFICIENCY IN FULLY ELECTRIC OPERATION

Unlike conventional diesel-powered sightseeing vessels, where fuel can be replenished as needed, battery-electric vessels rely on finite onboard energy storage and the availability of charging infrastructure. This makes energy efficiency critical across the entire operating profile.

For MS Rygerelektra, selecting the right propulsion system was key to achieving optimal range and performance for her 45-nautical-mile round trip to Pulpit Rock. A more energy-efficient propulsion system reduces the size of the battery pack needed, leading to a lighter vessel, lower energy consumption, and extended operational range.

As a sightseeing vessel, MS Rygerelektra runs at fluctuating speeds and under v arying load conditions. During a typical cruise, the vessel must navigate different speed zones up to 20 knots, including slow manoeuvres near scenic locations, moderate cruising speeds, and efficient transit speeds.

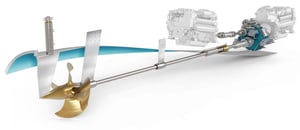

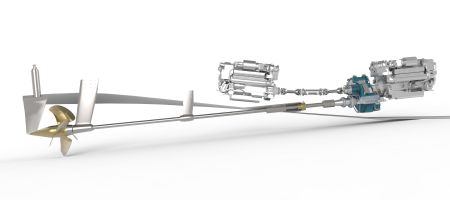

SERVOGEAR’S ECOFLOW PROPULSORTM

To overcome these challenges, Rødne Fjord Cruise selected Servogear’s Ecoflow PropulsorTM – a fully integrated propulsion performance in all operating scenarios.

Designed specifically for high-speed vessels and tailored according to each individual vessel’s requirements and unique operational profile, the system ensures minimal energy losses and optimal handling.

SERVOGEAR’S ECOFLOW PROPULSORTM

Effect Rudder

Learn More About Our Effect Rudder

Pitch Propeller Blades

Discover the Efficiency of Our Pitch Propeller Blades

Propeller Tunnel

Learn More About Our Advanced Propeller Tunnels

EACH SYSTEM INCLUDES:

- Propeller tunnel: Unique design ensuring optimal propulsor performance.

- Effect rudder: Asymmetric hydrofoil design, providing minimal drag and generating forward thrust.

- Controllable pitch propeller: Optimising load distribution and propulsion efficiency at all speeds.

- Shaft brackets: Streamlined design to minimise drag for high-speed operations.

- Gearbox: Compact design with versatile configurations and built-in servo system for pitch control.

Servogear’s scope of supply to MS Rygerelektra included the design and delivery of two Ecoflow propulsors.

PRINCIPLE ARRANGEMENT

MS RYGERELEKTRA

- Yard / Design: Brødrene Aa

- Hull design: Paradis Nautica

- Length and beam: 42m / 10,3m

- Material: Carbon Composite • Motor: 2 x Ramme 375 kW

- Battery capacity: 2,1 MWh

A SMOOTHER, MORE SUSTAINABLE SIGHTSEEING

The combination of lightweight carbon fibre construction, fully electric operations, and an optimised propulsion system delivers tangible benefits:

- Lower energy consumption: The vessel operates more efficiently, reducing charging frequency and extending range.

- Reduced environmental footprint: Zero CO₂ emissions ensure compliance with present and future regulatory requirements for tourist vessels operating in Norwegian fjords.

- Lower maintenance requirements: The electric system and optimised propulsion significantly reduce wear and tear compared to conventional engines.

- Quieter, smoother passenger experience: Reduced noise, vibration, and zero exhaust emissions enhance onboard comfort – elevating the sightseeing experience.

See the full case study on the hybrid/electric sightseeing vessel for operational insights

INFRASTRUCTURE AND CHARGING CONSIDERATIONS

While MS Rygerelektra has proven the feasibility of fully electric sightseeing operations, it also highlights the importance of robust charging infrastructure.

Initially, the vessel relied solely on slow charging, which took 7–8 hours to fully recharge the battery. This posed a challenge during peak tourist season when the vessel has two daily round trips. Without the ability to fully recharge between sailings, the operator had to rely on a combination of shore charging and range extenders to ensure sufficient energy for the second tour.

A long-awaited boost to the charging infrastructure arrived in spring 2025, when a high-capacity fast-charging solution was installed in Stavanger. With this in place, the operator expects MS Rygerelektra to complete two fully electric round trips per day. This situation, however, underscores a broader challenge for maritime electrification: while vessel technology is ready, ports must invest in high-capacity charging to support seamless zero-emission operations.

Beyond infrastructure, another initial challenge in the transition to electric operation was overcoming “range anxiety” among the crew – an unease that many early EV adopters can relate to. With experience, this anxiety was overcome within the first year and the crew are now fully comfortable with operating a battery-powered vessel. In this way, Rødne Fjord Cruise’s transition to fully electric operations has not only improved environmental performance but also strengthened the company’s internal expertise in zero-emission technology, and the knowledge gained from MS Rygerelektra has become highly valuable for the operator’s bidding processes on fast ferry routes that require or encourage low- and zero-emission vessels.

“To Rødne, Servogear has been a valued partner for 50 years. They have delivered superior propulsion efficiency to several of our vessels throughout the years and continued to do so as we transitioned to fully electric operations with MS Rygerelektra.

Servogear’s Ecoflow Propulsor™ system was a cornerstone for this vessel, ensuring optimal efficiency across varying speeds and load conditions. The system’s performance helps us maximise range and minimise charging time, allowing us to offer a more sustainable, silent and seamless fjord experience for our passengers.”

“Delivering propulsion solutions that enhance energy efficiency is at the core of what we do. Seeing MS Rygerelektra operate successfully with our propulsion system is incredibly rewarding.

Ecoflow PropulsorTM has made an already green solution even greener – and we are proud to contribute to the success of zero-emission vessel technology.” Photo: Morten Åkre Photo: David_Gonzalez Photo:

CONCLUSION

MS Rygerelektra exemplifies how zero-emission high-speed passenger transport is not only possible but operational today.

Its success highlights the importance of optimised propulsion in making electric vessels viable on a commercial scale.

With every new vessel, efficiency improvements continue to drive the maritime industry forward.

As infrastructure catches up with vessel technology, solutions like the Ecoflow Propulsor™ will play a critical role in shaping the future of sustainable passenger transport.

Get in Touch

Do you want to learn more about our solutions or discuss how we can support your next project? Our team of experts is ready to answer your questions and explore opportunities together.- Let’s talk about your needs

- Share your ideas with us

- Start building a sustainable and reliable future today

Explore More Resources

%20Propulsion%20Systems%20from%20Servogear.jpg?width=300&name=Controllable%20Pitch%20Propellers%20(CPP)%20Propulsion%20Systems%20from%20Servogear.jpg)